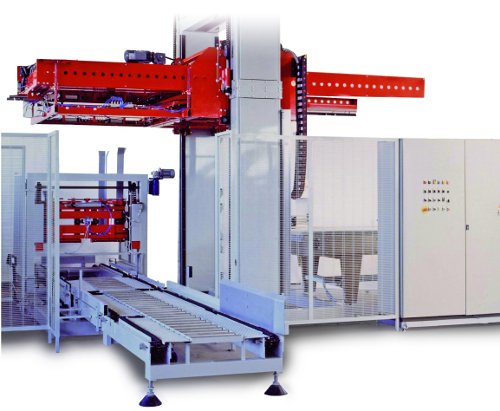

Depalletizer for bottles, cans and jars with steady pallet and low level outfeed

MODEL: “A.DL.101.L”

PRODUCTION: Up to 3 layers/minute

TECHNICAL DESCRIPTION AND MAIN FEATURES

- Machine with stady pallet and low level outfeed for containers

- Independent mobile centering device to grant stability during interlayer pad picking up and during layer depalletizing

- Sweeping type layer transfer system to handle different container sizes

- Intermediate layer transfer platform

- Layer receiving mat

INNOVATIVE ELEMENTS

- Suitable for medium speed lines

- Maximum lay-out flexibility

- Functioning without operator

- Optimization of change over time

- Long-term reliable performances

OPTIONS

- Possibility to install a layer transfer unit head with inflatable pipes, with vacuum plate, with suction cups or with magnetic plate in place of sweeping type layer transfer system

- Standard multi-chains aligner or no-pressure aligning system at depalletizer outlet

- Automatic or semi-automatic version

ACCESSORIES

- Automatic system to remove interlayer pads, trays or reverse trays, top frames